Overview of Project Progress

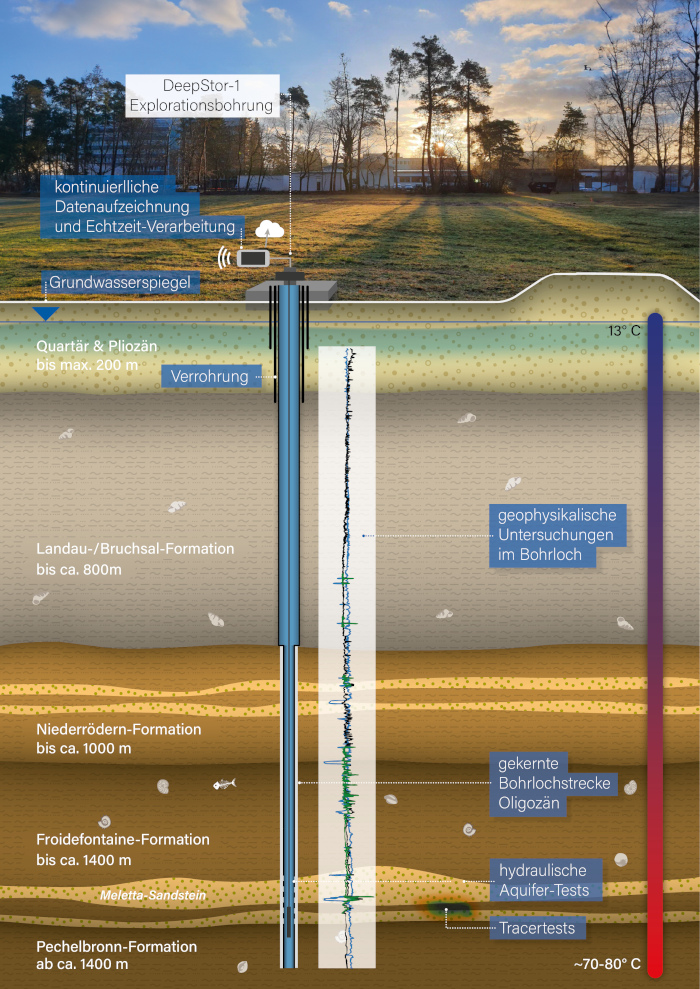

The DeepStor research initiative encompasses a sequence of meticulously choreographed tasks that are both scientifically and technically demanding. All measures, ranging from the establishment of hydrogeological monitoring infrastructure and detailed geophysical characterizations to the planned exploration drilling, are meticulously planned, documented, and evaluated on the basis of data. The objective of the research initiative is to document the characteristics of prospective deep storage formations on the KIT North Campus, and to methodically assess their suitability for high-temperature heat storage (HT-ATES). The subsequent section offers an overview of the present project status, significant milestones, and ongoing research activities.

2026/01: Installation of the Conductor Pipes Successfully Completed

Completion of Conductor Pipe Installation

Following a brief delay due to subsurface conditions, the installation of the conductor pipes was successfully completed on Monday, January 19, 2026. With the completion of these preparatory measures, a key technical milestone has been reached for the continued implementation of the DeepStor exploration drilling.

We would like to thank everyone involved for their understanding and patience.

2026/01: Installation of the Conductor Pipes

Performing the Conductor Pipe Installation

As part of the preparations for the DeepStor exploration drilling, the service provider Wagenborg Foxdrill is currently installing the conductor pipes. The implementation of these large-diameter steel pipes is crucial for stabilizing the upper section of the borehole, ensuring the protection of groundwater and facilitating the safe execution of subsequent drilling operations. The hydraulic impact hammer driving method is an environmentally friendly installation technique that offers an efficient alternative to conventional drilling and cementing methods.

The conductor pipes are made from standard-compliant steel pipes and installed in individual sections, ensuring precise alignment and safety. The individual pipe segments are positioned on site, precisely aligned, and extended using full-penetration welded connections. A dedicated guidance system with roller guides is used to ensure vertical alignment. Geometric control is maintained through the implementation of surveying techniques.

The selected driving method is characterized by a short construction period, minimal site preparation, and effective hydraulic sealing between the pipe and the surrounding soil. The construction activities are scheduled to commence in mid-January 2026. During the installation process, there is a possibility that temporary elevated noise levels and ground vibrations may be experienced. However, these effects are time-limited and are closely monitored as part of the project's comprehensive monitoring program.

2025/11: Installation of Groundwater Monitoring Wells

Establishing a Groundwater Monitoring Network

As part of the preparations for the DeepStor exploration drilling project, new wells are currently being installed to ensure the protection of the groundwater (November/December 2025). These wells are a key component of the project's comprehensive environmental and safety strategy. Continuous monitoring of local groundwater conditions allows for the early detection and assessment of changes.

The establishment and operation of a groundwater monitoring system with seven monitoring wells is planned. Following the completion of the project, hydraulic tests will be conducted and groundwater samples will be collected. These samples will be used to determine the natural baseline composition of the intercepted groundwater, also known as the baseline measurement. Initial analyses will be performed by a testing laboratory accredited in accordance with DIN EN ISO/IEC 17025 to ensure high data quality and comparability. For ongoing monitoring, sensors will be installed within the screened intervals of the wells. These sensors will record parameters such as temperature and electrical conductivity. These parameters will be used as indicators of potential inputs. In addition, regular sampling and analytical campaigns will be carried out to reliably document any changes.

Approval of the groundwater monitoring concept was granted through a separate water-law permitting procedure. This approach ensures that all measures comply with scientific and regulatory requirements while simultaneously establishing a robust data basis for the further development of the DeepStor project.

2025/10: DeepStor-1 | Approval of the Main Operating Plan

The DeepStor-1 main operating plan has been approved

At the North Campus of the Karlsruhe Institute of Technology (KIT), the approval of the primary operating plan for the DeepStor-1 exploration well has established the foundation for the subsequent development of contemporary geothermal heat storage technologies. The objective of the DeepStor project is to investigate the effective storage of surplus heat from summer months in deep subterranean reservoirs and its subsequent utilization during winter months in a manner that is environmentally sustainable. The basis for this will initially be provided by data from a borehole around 1,400 meters deep on the North Campus, from which around 700 meters of rock will be extracted as drill cores and then examined. The analysis of these drill cores will provide information about the properties of the various geological formations.

The subsequent phases of the project entail site preparation, the initiation of peripheral construction in fall 2025, and the installation of conductor pipes to safeguard the groundwater. The drilling is scheduled to commence in the second quarter of 2026. The implementation of close seismic monitoring, which utilizes seismometers, vibration meters, Raspberry Shakes, and fiber optic DAS, has been demonstrated to enhance safety and transparency. A traffic light system has been developed to ensure that unusual ground vibrations are immediately detected, evaluated, and communicated.

.